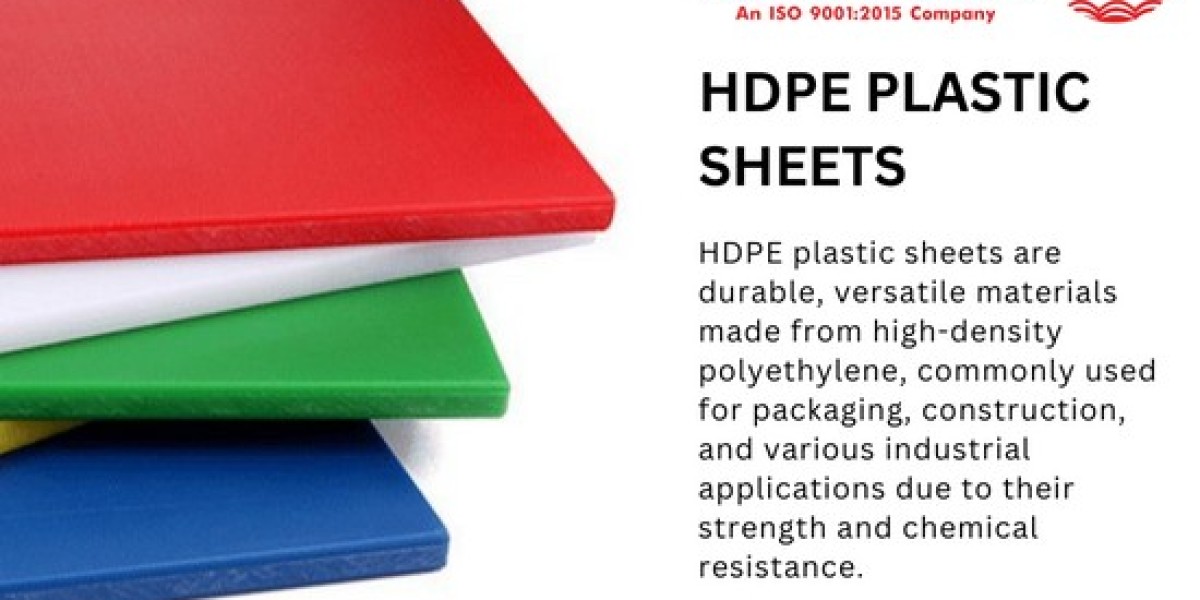

In the world of plastics, High-Density Polyethylene (HDPE) stands out as a material with remarkable versatility and durability. HDPE Sheet Manufacturers in Gujarat, in particular, have gained widespread popularity across various industries due to their exceptional properties and myriad applications. From construction to packaging, and from agriculture to healthcare, HDPE plastic sheets have become indispensable. Let's delve into the world of HDPE plastic sheets, exploring their uses, benefits, and frequently asked questions.

Understanding HDPE Plastic Sheets:

HDPE, a thermoplastic polymer, is renowned for its high strength-to-density ratio and resistance to various chemicals and solvents. HDPE plastic sheets are manufactured through a process of extrusion, resulting in flat, flexible sheets of varying thicknesses. These sheets exhibit excellent flexibility, impact resistance, and weatherability, making them suitable for both indoor and outdoor applications.

Applications of HDPE Plastic Sheets:

Construction: HDPE Sheet Suppliers in Ahmedabad find extensive use in the construction industry for applications such as moisture barriers, temporary floor protection, and concrete formwork. Their resistance to moisture and chemicals, coupled with their lightweight nature, makes them ideal for such purposes.

Packaging: HDPE plastic sheets are widely employed in packaging applications, including the fabrication of bottles, containers, and packaging films. Their ability to withstand varying temperatures and resist punctures ensures the safe transportation and storage of goods.

Agriculture: In agriculture, HDPE plastic sheets serve multiple functions, ranging from greenhouse coverings and mulching films to irrigation liners and livestock shelters. Their durability, UV resistance, and impermeability to water make them indispensable for modern agricultural practices.

Healthcare: Within the healthcare sector, HDPE plastic sheets are utilized in the fabrication of medical trays, laboratory equipment, and protective barriers. The material's non-toxic nature, ease of sterilization, and resistance to chemicals make it ideal for maintaining hygienic environments.

Signage and Displays: HDPE plastic sheets are also popularly used in signage and display applications due to their lightweight nature, ease of printing, and durability. From outdoor signage to indoor displays, HDPE sheets offer a cost-effective solution with vibrant visual appeal.

Benefits of HDPE Plastic Sheets:

Durability: HDPE Sheets Manufacturers in India are renowned for their durability and longevity, making them a cost-effective investment in the long run.

Chemical Resistance: These sheets exhibit high resistance to a wide range of chemicals, acids, and solvents, ensuring their suitability for diverse industrial applications.

Weatherability: HDPE plastic sheets are resistant to UV radiation, moisture, and extreme weather conditions, making them suitable for outdoor use without degradation or discoloration.

Ease of Fabrication: HDPE sheets can be easily cut, drilled, and fabricated using standard tools, allowing for customization according to specific requirements.

Recyclability: HDPE is a highly recyclable material, contributing to environmental sustainability and reducing waste in landfills.

Conclusion:

HDPE plastic sheets represent a versatile and durable solution for a myriad of applications across various industries. From construction and packaging to agriculture and healthcare, the unique properties of HDPE make it a preferred choice for manufacturers and designers seeking reliability and performance. With their exceptional durability, chemical resistance, and recyclability, HDPE plastic sheets continue to shape the future of modern engineering and design.

Frequently Asked Questions (FAQs):

Q1: What are the key differences between HDPE and other types of plastic sheets?

A1: Unlike other plastics, HDPE exhibits high strength-to-density ratio, excellent chemical resistance, and UV stability, making it suitable for a wide range of applications where durability is essential.

Q2: Can HDPE plastic sheets be used for food contact applications?

A2: Yes, HDPE plastic sheets are FDA-approved for food contact applications due to their non-toxic nature and resistance to chemicals.

Q3: Are HDPE plastic sheets environmentally friendly?

A3: HDPE is a highly recyclable material, and many manufacturers offer recycled HDPE sheets, contributing to environmental sustainability.

Q4: What thicknesses are available for HDPE plastic sheets?

A4: HDPE plastic sheets are available in a wide range of thicknesses, typically ranging from 0.030 inches to 1.00 inch or more, depending on the application requirements.

Q5: Can HDPE plastic sheets be welded?

A5: Yes, HDPE plastic sheets can be welded using hot air or extrusion welding techniques, allowing for seamless fabrication of large structures and components.