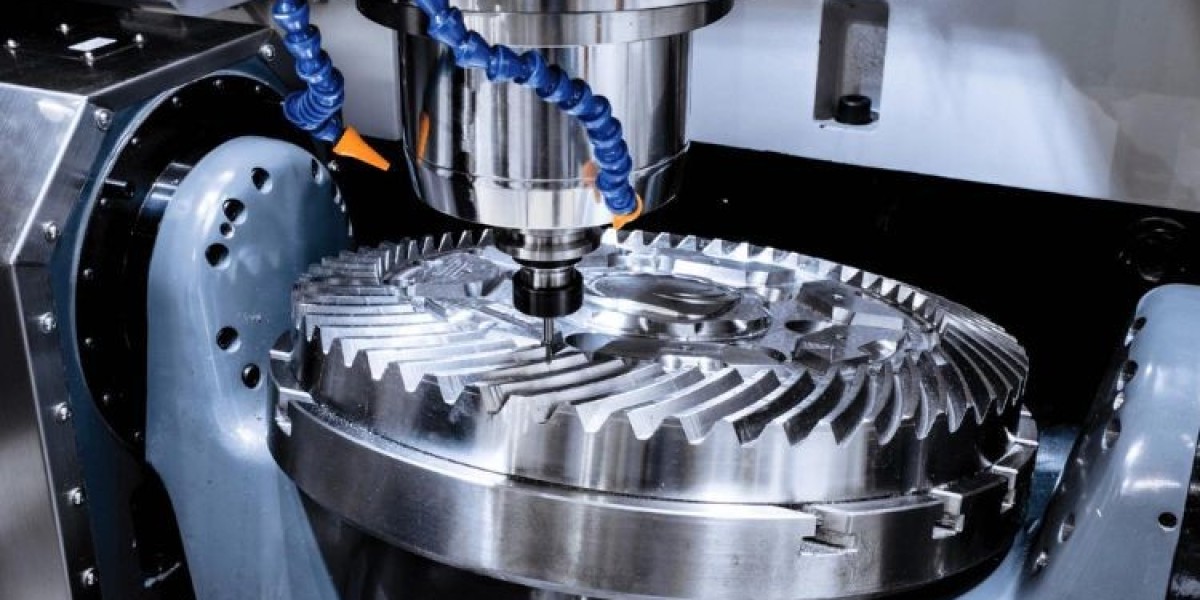

The global milling machine market size attained a value of USD 84.26 billion in 2023. The milling machine market is further expected to grow in the forecast period of 2024-2032 at a CAGR of 7.2% to reach USD 157.02 billion by 2032. The Asia Pacific is the fastest-growing market for the product. Milling machines play a crucial role in various industries, offering precision and efficiency in manufacturing processes. This blog post delves into the market analysis, share, and forecast of the global milling machine market, segmented by mechanism, direction, end use, and region, and provides a comprehensive view of the competitive landscape.

Market Segmentation by Mechanism

Fraction Rice Milling Machine

Fraction rice milling machines are integral in the agricultural sector, particularly in rice processing. These machines separate the rice grains from the husk and bran layers, ensuring high-quality rice production. The demand for fraction rice milling machines is driven by the increasing consumption of rice globally. As more countries focus on improving their agricultural outputs, the market share for these machines is expected to witness significant growth. The adoption of advanced milling technologies in rice processing also contributes to the market expansion.

Grind Rice Milling Machine

Grind rice milling machines, known for their ability to grind rice into fine flour, are essential in the food processing industry. These machines cater to the rising demand for rice flour, a staple ingredient in many cuisines and food products. The market for grind rice milling machines is anticipated to grow due to the increasing popularity of gluten-free products and the health benefits associated with rice flour. Innovations in grinding technology and efficiency enhancements further bolster the market growth.

Market Segmentation by Direction

Vertical Type Mill Rollers

Vertical type mill rollers are widely used in the milling industry due to their compact design and high efficiency. These rollers are ideal for applications requiring high precision and uniform milling. The vertical design allows for better space utilization and easier maintenance, making them a preferred choice in various industries. The market for vertical type mill rollers is expected to grow as industries continue to seek efficient and space-saving milling solutions.

Horizontal Mill Rollers

Horizontal mill rollers are known for their robust construction and versatility in handling different materials. These rollers are commonly used in large-scale milling operations, including those in the construction and automotive sectors. The horizontal design facilitates easier handling of larger workpieces and provides greater stability during the milling process. The market for horizontal mill rollers is projected to expand as industries invest in robust and versatile milling equipment to enhance their production capabilities.

Market Segmentation by End Use

Automotive

Milling machines are indispensable in the automotive industry for manufacturing precision parts and components. The demand for milling machines in this sector is driven by the need for high-quality, reliable, and efficient manufacturing processes. As the automotive industry continues to innovate and develop new technologies, the market for milling machines is expected to see substantial growth. Key trends include the adoption of automation and advanced CNC milling technologies to improve production efficiency and reduce costs.

Aerospace and Defence

The aerospace and defence sectors rely heavily on precision milling machines for manufacturing critical components. The stringent quality standards and the need for high-precision parts make milling machines a vital part of the production process. The market for milling machines in the aerospace and defence industries is anticipated to grow due to increasing defence budgets and the expansion of commercial aviation. The focus on lightweight materials and complex geometries further drives the demand for advanced milling technologies.

Construction Equipment

In the construction equipment industry, milling machines are used for manufacturing parts and components for various machinery. The robust construction and reliability of milling machines make them essential for producing durable and high-performance construction equipment. The market demand is fueled by the growth in infrastructure projects and the increasing need for efficient construction machinery. Innovations in milling technology, such as the development of more durable and efficient machines, contribute to market growth.

Others

Other significant industries utilizing milling machines include electronics, medical devices, and general manufacturing. The versatility of milling machines in handling various materials and applications makes them a crucial part of these industries. The market for milling machines in these sectors is expected to grow as industries continue to seek precision and efficiency in their manufacturing processes.

Regional Analysis

North America

North America holds a significant share of the global milling machine market due to the presence of advanced manufacturing industries and the adoption of innovative technologies. The region's focus on automation and efficiency in production processes drives the demand for milling machines. The market is expected to grow steadily, supported by continuous technological advancements and investments in manufacturing infrastructure.

Europe

Europe is a prominent market for milling machines, with a strong presence of automotive and aerospace industries. The region's emphasis on precision engineering and high-quality manufacturing contributes to the demand for advanced milling technologies. The market in Europe is projected to grow, driven by innovations in milling processes and the increasing adoption of automation.

Asia Pacific

The Asia Pacific region is the fastest-growing market for milling machines, attributed to the rapid industrialization and expanding manufacturing sector. Countries like China, India, and Japan are leading contributors to the market growth. The increasing focus on improving manufacturing efficiency and adopting advanced technologies propels the demand for milling machines. The market is expected to witness substantial growth, supported by government initiatives and investments in industrial development.

Latin America

Latin America shows potential for growth in the milling machine market, driven by the development of manufacturing industries and infrastructure projects. The region's focus on improving production capabilities and efficiency contributes to the market expansion. The adoption of advanced milling technologies and increasing investments in manufacturing infrastructure are expected to drive market growth.

Middle East and Africa

The Middle East and Africa region present opportunities for growth in the milling machine market, primarily driven by the development of industrial sectors and infrastructure projects. The market demand is supported by the increasing need for efficient and reliable manufacturing equipment. The adoption of advanced milling technologies and investments in industrial development are expected to contribute to market growth.

Competitive Landscape

Major Players in the Milling Machine Market

The global milling machine market is highly competitive, with several key players dominating the market. Major companies include:

- DMG MORI

- Mazak Corporation

- Okuma Corporation

- Haas Automation Inc.

- Makino Milling Machine Co., Ltd.

These companies focus on continuous innovation, advanced technologies, and strategic partnerships to strengthen their market positions. Recent developments include the introduction of automated and CNC milling machines, enhancing production efficiency and precision.

Market Forecast 2024-2032

Growth Projections and Future Trends

The milling machine market is projected to grow significantly, driven by the increasing demand for precision and efficiency in manufacturing processes. Key trends include the adoption of automation, advanced CNC milling technologies, and innovations in milling processes. Economic and regulatory factors, such as government initiatives to boost industrial development, are expected to positively impact market growth. The market is anticipated to reach USD 157.02 billion by 2032, growing at a CAGR of 7.2%.